7 minute read

This guide explores the high-pressure fuel injector, a crucial component in modern engines. These precision devices improve fuel efficiency and contribute to a cleaner environment. They transform a simple drip into a finely atomized mist, enabling better combustion. The guide delves into their unique features, applications, and technical evolution, discussing their impact on fuel economy and emissions reduction. It also addresses common issues and the future of this vital technology. For those interested in their specific application in diesel engines, resources on high pressure diesel injectors can provide deeper insights.

From Drip to Mist: What Makes High-Pressure Injectors Different?

Due to their superior atomization, high-pressure injectors are essential for fuel injection in engines. They force fuel through tiny orifices at extreme pressures, creating a super-fine mist that increases the fuel’s surface area, allowing it to mix more thoroughly with air. This improved mixing is crucial for efficient combustion, as poorly atomized fuel may result in wasted energy, reduced power, and increased emissions. High-pressure injection ensures every fuel molecule is exposed to oxygen, improving fuel efficiency and engine performance.

The Leap from Port Injection to Direct Injection

Historically, gasoline engines used port fuel injection (PFI), which sprays fuel onto intake valves. Direct Injection systems like GDG and CD spray fuel directly into the engine’s combustion chamber, allowing greater control over fuel-air mixture and combustion process. PFI systems operate at low pressures, while direct injection systems demand higher pressures for atomization. Advanced fuel injection systems use high-pressure injectors for high injection pressures.

The Symphony of Combustion: How High-Pressure Injection Systems Work

High-pressure injection systems are intricate operations controlled by the Engine Control Unit (ECU), which monitors engine parameters like speed, load, temperature, and oxygen levels. These systems can perform multi-pulse injection, ensuring smooth combustion, power, and emissions control. The rapid response times and precise control provided by high-pressure injectors enable this.

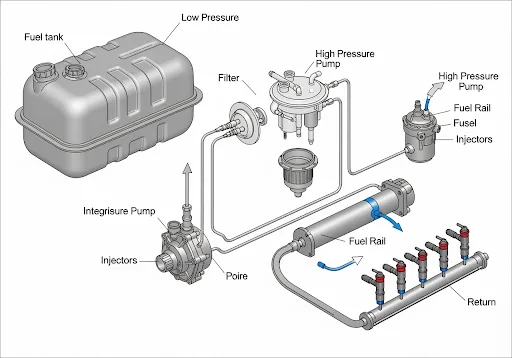

The Role of the High-Pressure Fuel Pump and Rail

High-pressure systems use fuel from the tank to a high-pressure fuel pump, which can handle immense pressures, such as 2,500 psi (GDI) or 1500-2500 Bar (modern diesels). The fuel is then delivered to the fuel rail, acting as a common reservoir and dampening pressure fluctuations caused by individual injector firing. Fuel quality is crucial in these systems as it is a combustible medium and lubricant.

Electronic Precision: Solenoid vs. Piezoelectric Actuators

The actuator in an injector controls fuel flow. There are two main types: solenoid injectors and piezoelectric injectors. Solenoid injectors are robust and widely used, while piezoelectric injectors offer advanced technology like faster response, multiple injections per cycle, finer control, and reduced noise and emissions. Despite being more expensive, piezoelectric injectors offer performance, efficiency, and emissions reduction benefits, making them increasingly common in high-end engines.

More Power, Less Pollution: The Benefits of High-Pressure Fuel Injection

High-pressure injection technology has revolutionized engine design and performance, delivering substantial advantages in power output and environmental impact.

Boosting Fuel Economy and Engine Performance

High-pressure injection enhances combustion efficiency by creating a finer fuel spray, allowing fuel to mix more closely with air, leading to a more complete and rapid burn. This results in better fuel economy, higher output and torque from smaller displacement engines, and precision control over injection, which optimizes timing and contributes to power delivery and responsiveness.

A Greener Footprint: Reducing Harmful Emissions

High-pressure injection is crucial for meeting global emission regulations like Euro 6 and EPA standards, as it facilitates more complete combustion and reduces harmful pollutants. It offers sophisticated NOx control strategies, including precise multi-pulse injection events and fuel injection during exhaust stroke for aftertreatment system regeneration. This precise fuel control also benefits cold-start emissions, allowing for quicker catalyst light-off and reduced emissions during critical periods.

The Evolution and Future of High-Pressure Injectors

Fuel injection technology’s journey has been continuous innovation, driven by the relentless pursuit of greater efficiency, power, and reduced emissions.

From Mechanical to Smart Electronically-Controlled Devices

Early fuel injection systems were mechanical, relying on cams and springs. High-pressure injection systems like the Unit Injector System (UIS) integrated the pump and injector, allowing higher pressures. Electronic control led to precise timing and solenoid control in injectors. Hydraulically Actuated Electronic Unit Injection (HEUI) bridged mechanical and electronic control, allowing independent pressure generation regardless of engine speed. Common rail is the preferred architecture for modern high-pressure fuel injection due to its flexibility and performance.

What’s Next? The Future of Fuel Injection Technology

High-pressure injectors are expected to reach even higher pressures, possibly exceeding 3,000 bar, to achieve finer atomization and complete combustion. Advanced control algorithms will refine injection strategies, optimizing performance and emissions across various operating conditions. AI-driven self-learning systems may adapt injection patterns in real-time. High-pressure injectors will be crucial in transitioning to alternative fuels like hydrogen, biofuels, and synthetic fuels, with greater system integration for holistic efficiency and performance.

Health Check: Diagnosing and Maintaining Your Injection System

High-pressure injectors are precision components operating under extreme conditions. Like any critical engine part, they require proper care and attention to ensure longevity and optimal performance. Preventive maintenance is key to avoiding costly repairs down the line.

Standard Failure Modes for High-Pressure Injectors

High-pressure injectors can fail due to various factors, including clogged nozzles, internal wear, leaking seals, solenoid failure, piezo stack failure, and a sticking needle valve. Clogged nozzles can cause fuel inconsistencies, internal wear can cause inconsistencies, leaking seals can lead to excessive fuel consumption, solenoid failure can occur from overheating or wire fatigue, and piezo stack failure requires specialized tools and advanced diagnostic equipment.

The Critical Role of Fuel Quality and Maintenance

Fuel quality is crucial for high-pressure injectors’ longevity and performance, as it lubricates and cools components. Contamination can damage injector orifices and pump surfaces, while water contamination can cause corrosion and rapid wear. Diesel fuel’s lubricity is essential for high-pressure components, and low-sulfur diesel can reduce it. High-quality diesel fuel additives can maintain cleanliness and lubricity. Operating conditions like frequent short trips, prolonged idling, or extreme temperatures can stress the fuel system.

Frequently Asked Questions about High-Pressure Injectors

Can you clean high-pressure injectors?

High-pressure injectors can be cleaned using professional services, ultrasonic baths, and specialized solvents. However, cleaning cannot resolve issues related to internal wear, such as worn needle valves or plungers. If an injector has significant mechanical wear, cleaning may only be temporary or may be no solution. In such cases, replacement vs. cleaning is crucial. Consult a qualified technician to diagnose the injector’s condition properly and ensure the correct amount of fuel is delivered.

What’s the main difference between GDI and Common Rail injectors?

GDI and Common Rail systems use high-pressure injectors for fuel delivery, with GDI injectors handling gasoline and Common Rail injectors handling diesel fuel. Diesel engines operate at higher pressures, affecting injector components’ robustness. GDI engines use spark ignition, while diesel engines use compression ignition, affecting timing and spray pattern requirements. Diesel combustion produces more soot, necessitating complex nozzle designs and multi-injection capabilities.

How long do high-pressure injectors last?

High-pressure injectors can last 100,000-150,000 miles or more, depending on fuel quality, maintenance schedule, driving habits, manufacturer variation, and operating conditions. Consistent use of clean fuel, adherence to maintenance schedules, and proper maintenance can extend injector life. Early detection and repair are crucial to prevent further damage to the fuel system or engine.

Conclusion: The Precision Powerhouse

High-pressure injectors are crucial in modern engine technology. They transform fuel into atomized mist at high pressures for power, fuel economy, and reduced emissions. Their intricate components, including electronics and piezoelectric actuators, enable precise fuel metering and rapid-fire capabilities. As emission standards increase, these injectors will continue to evolve, requiring proper care and maintenance for optimal performance.