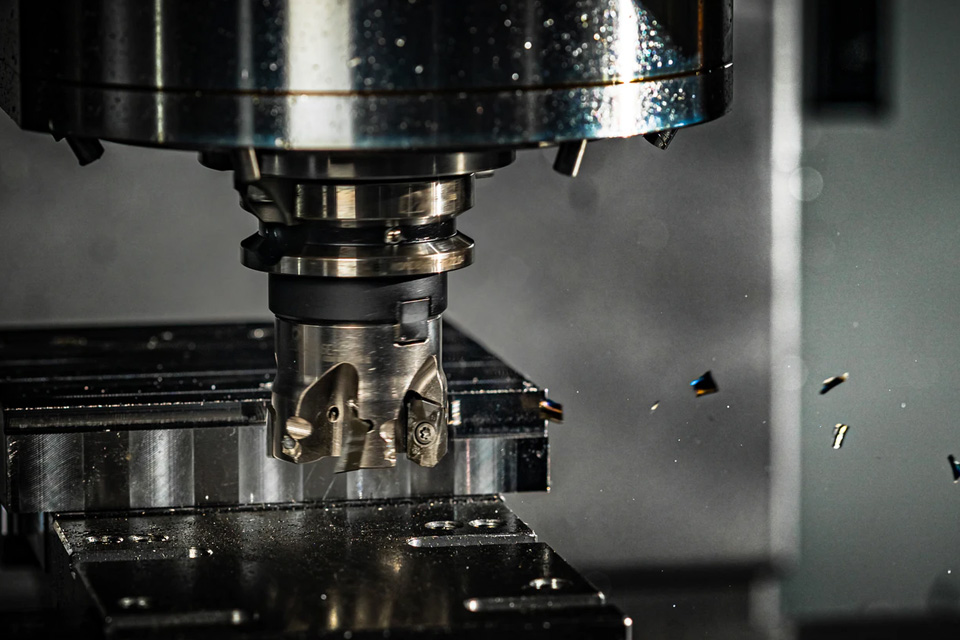

The manufacturing process of Computerized Numerical Control machining is used in various industries. CNC machines work by sending computerized instructions to motorized tools like drills and lathes. The tools then use those instructions to create parts from a block of material. CNC machines can be used to produce precise parts from various materials, such as metals and plastics.

The simplicity, efficiency, and preciseness of CNC machining have made it a popular choice for manufacturing parts in the automotive industry. For instance, it can be used to manufacture some of the key components of a car’s combustion engine. An example is turning a large aluminum block into a cylinder block that will contain the engine’s cylinders. CNC machining can also be used with materials like acrylic glass and PMMA to produce headlights and interior lighting for a vehicle. Other vehicle parts that are manufactured via CNC machining include carburetor housings, exhaust parts, suspension components, bushings, fluid system components, and valve retainers. Let’s take a closer look at the advantages of using CNC machining in the automotive industry.

Increased Production Speed

The main advantage of CNC machining parts for vehicles is the speed the process provides. Because the instructions for machining are carried out automatically by a computer, human limitations do not need to be factored into the manufacturing process. That advantage becomes more apparent when parts are produced in high volume, as the computer instructions can be repeated in exactly the same way as many times as required. At the end of the day, CNC machining is faster than conventional machining, which is why many companies, not only in the automotive industry, are turning to CNC machines to enhance their production capabilities. If you are just getting started with CNC manufacturing, check out Revelation Machinery’s services. The company provides an unparalleled service in the buying and selling of fabrication and CNC machinery.

Accuracy

CNC machines provide better accuracy than many other manufacturing machines, due to the machinery’s autonomous nature. The CNC machining process leaves only a very small margin for errors occurring. The finest CNC machine settings provide tolerances of ±0.001″. With such high accuracy and precision, the automotive industry can maintain the highest standards every time a part is produced.

Repeatability

Unlike traditional manufacturing methods, CNC machines can produce the same part again and again without any inconsistency. Therefore, CNC machining becomes an extremely useful method to produce large volumes of a single part. Seeing as millions of cars are manufactured and sold every year, the demand for large volumes is constant in the automotive industry.

Cost-effectiveness

Seeing as machining large volumes of parts is less labor-intensive with CNC machining, it means CNC machining is more cost-effective than other manufacturing processes. That means workers have more time to focus on innovation and design.

Other Advantages

The advantages of CNC machining in the automotive industry and other industries are far-reaching. Here are just a few of the other benefits CNC machines provide:

- CNC tools can produce any shape, size, or precise placement that is required.

- The machines work continuously to meet demanding deadlines, only needing to stop for occasional regular maintenance.

- Updates are automatic to provide the latest and most capable programming.

- CNC machines accept designs and specifications from a number of compatible software programs.

- CNC machining gives broader capability than even the most skilled engineers because CNC tools can do things a human operator with a manual machine simply cannot do.

- CNC machining eliminates the challenges of manual-machining, such as staff shortages, vacations, and illnesses.